| Application | |||

|---|---|---|---|

| This grade is moisture reactive hot melt adhesive. It can be applied on the lamination of textile, textile/TPU film…etc. |

| Technical Product Data | |

|---|---|

| Appearance | Semi-yellowish, half transparent and half solid form (at room temperature) |

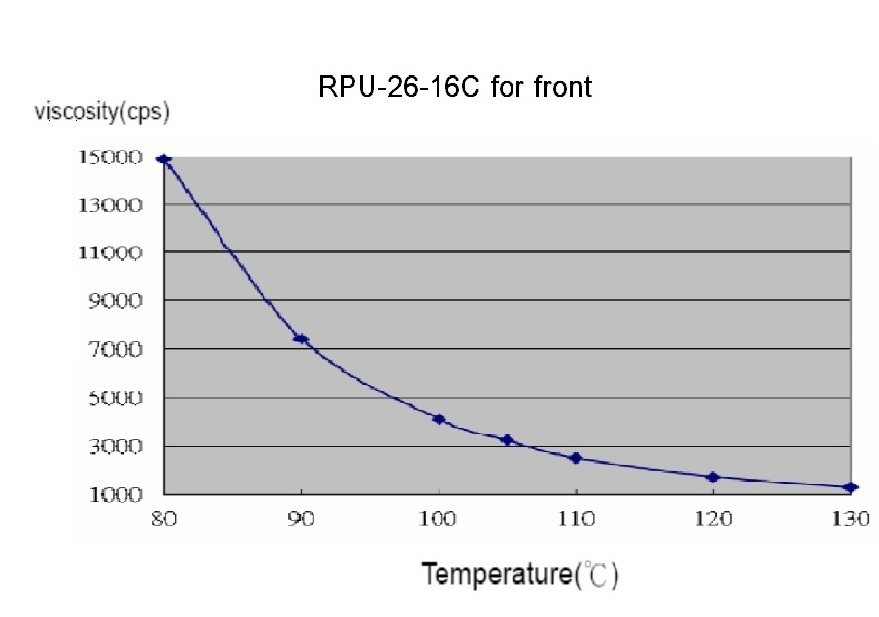

| Viscosity | 3250-3800 cps (105℃, Brookfield DV-II +,Sp.27, 50RPM) |

| Solid content | 100% |

| Component | Polyurethane resin |

| |

| * These items are provided as general information only. They are approximate values and are not considered part of the product specification. | |

| Characteristics | ||

|---|---|---|

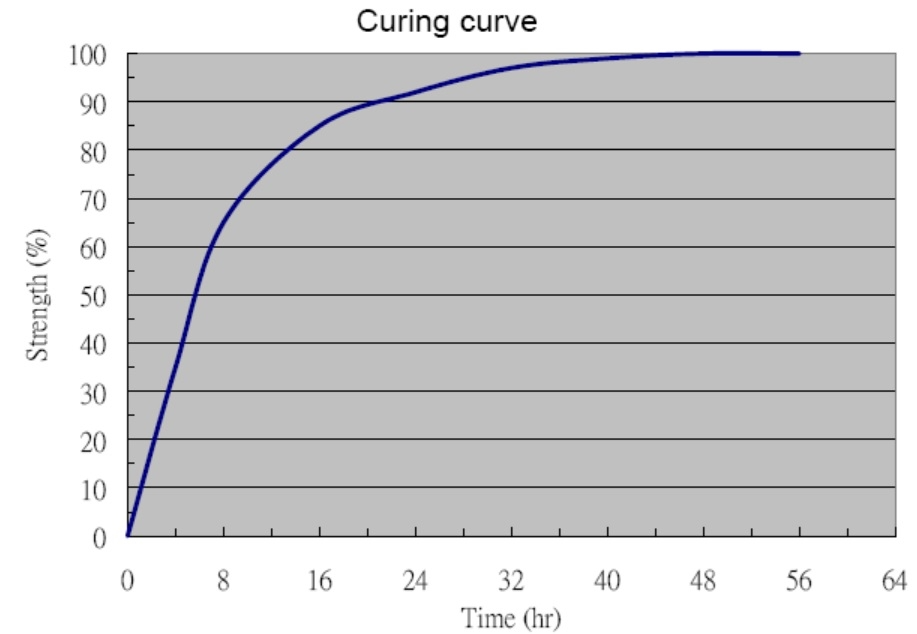

| RPU-26-16C is non-solvent environmental PU based moisture reactive hot melt adhesive. It can be applied on the lamination of textile, textile/TPU film…etc. According to the water repellent treatment material, it has the great bonding strength, viscosity, water resistance and resists chemical, yellowing, water hydrolysis and high temperature (<120℃). The water-repellent treatment fabric is 4 grade. Thus, its lowest operation temperature is 100-120℃, and its curing curve is as above. The table of the solvent resistance is as below. | ||

| Pass | Fail | |

| Toluene | ○ | |

| MEK | ○ | |

| Perchloroethylene | ○ | |

| DMF | ○ | |

| **The bonded textiles are put into the above different solvents at the room temperature for more than 2 weeks. The bonded textiles are not peeled off. | ||

| Operation process | |||

|---|---|---|---|

|

| Notice of reactive hot melt adhesive | |||

|---|---|---|---|

| |||

| Notice: These values are based on the test of our present laboratory test specimens |

Taiwantrade.com and iDealEZ.com uses analytical cookies and other tracking technologies to offer you the best possible user experience. By using our website, you acknowledge and agree to our cookie policy.

For more information on cookies or changing your cookies settings, read Taiwantrade & iDealEZ’s Privacy Policy.